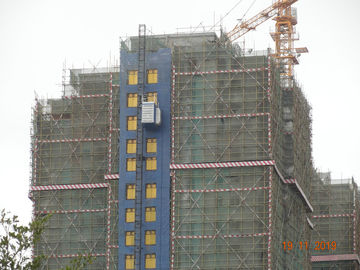

EN 12159 2012 2500KG Rack & Pinion Personnel Hoist System

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Description | Personnel Hoist System | Model | SC250/250(BG) KP-B20 |

|---|---|---|---|

| Purpose And Uses | Vertical Transportation Of Man And Materials In Construction Site Or Building Site | Design | According To European Standard |

| Material | Q345B Steel | Feature | High Safety |

| Highlight | rack & pinion hoist system,2500KG Personnel Hoist |

||

High Safety EN 12159:2012 Personnel Hoist System

Personnel Hoist System Details

1. Delicate design, comfortable driving experience.

2. Mature Helical Gear Transmission Technology.

3. The rack is located in the middle of the mast section.

4. Two kinds of configurations.single cage and double cage without counter weight.

5. Frequency conversion controlment ,stopping in the named floor accuratly.

6. Our hoist can provide different ways to attach a wall.

7. Optional painted or galvanized mast section,optional painted.

8. Durable materials: the adoption of high-strengh steel can increase the strength of the framework and reduce the dead load of the cage at the same time.

9. Many other configuration and function for your choosing.

10. New driver hoist can be operated safely and simply ,work in low running cost.

Personnel Hoist System Features and Advantages

* The material hoist runs without vibration or trembling. The man and material lift starts and stops without surging or jerking.

* The passenger and elevator is reliable with very little breakdown and is durable with very long work-life.

* Adopt energy-saving helical reducers which are made specially for rack and pinion elevators only. The construction hoist reducers are extremely strong, reliable and durable.

* Racks centering at mast reduce partial load torque of builders hoists, makes the construction hoists run more stably and smoothly.

* Applying non-eccentric rollers, make the installation of construction site elevators be faster and easier, with much less error.

* The integrated elevator car roof, which made by a steel plate with edges fully welded one time to complete, enhance hoist cage strength and ensure no water leakage.

* Easy access to electrical panels of elevator for maintenance.

* Certified safety braking system of rack and pinion hoist.

* The elevators are equipped with full set of safety facilities, including centrifugal brake, limit switches, Electromechanical interlocks.

* Frequency control unit (FC), with closed-loop, which gives the passenger and material hoists very smooth starting and stopping with low starting current and less wear and tear.

Technical Data

| Item & Article No. | SC250/250(BG) KP-B20 |

| Payload Capacity | 2500 KG per Cage |

| Lifting Speed | 0–80 m/min. |

| Max. Lifting Height | 450 m |

| Cage width (internal) | 1.5 m |

| Cage length (internal) | 3.2 m |

| Cage height (internal) | 2.35 m |

| Motor Control | Frequency Control |

| Engine Power | 3x38 KW per Cage |

| Gearbox | Helical Gearbox |

| Safety Device Type | Centrifugal Brake |

| Power Supply Range | 380–500 V, 50 or 60 Hz, 3 Phase |

| Mast Section | Square Column 650*650*1508 mm with Bolted Rack |

| Rack Module | 8 |

| Details of the Equipment | ||

| Item | Dimension/Specification | Material & Process |

| Standard Configuration | ||

| Cage Internal Size | 3.2(L)*1.5(W)*2.35(H) Meters | Perforated Galvanised Cold Roll Steel Plate |

| Cage Frame | Optimized and Strengthened Structure | Q345B Steel |

| Cage Paint | Yellow | Sandblasting and Painted |

| Cage Entry Door | Vertical Sliding | Galvanised Perforated Cold Roll Steel Plate |

| Cage Exit Door | Vertical Sliding/Flap Type | Galvanised Perforated Cold Roll Steel Plate |

| Driver's Cabin | Excluded/Included | |

| Motor Make | LUCASA make | |

| Gearbox | Kangbo Make Pieli Brand Helical Gearbox | |

| Mast Section | 650*650*1508mm, Φ76mm, δ4.5mm | Q345B Steel, Painted |

| Rack | 40*60*1508mm, 8 Modulus. | |

| Tie-in | Type II, 2900-3400mm; Every 9 m one set; | |

| Or as per users request | ||

| Safety Device | SAJ50-2.0 | |

| Ground Enclosure | Galvanised Cold Roll Steel Plate | |

| Enclosure Door | Double Hinge Side Open Door | Perforated Galvanised Cold Roll Steel Plate |

| Power Supply | Cable & Cable Drum | Galvanised Cold Roll Steel Plate |

| Over Load Protect | Included | |

| Optional Configuration | ||

| Mast Section | 650*650*1508mm, Φ76mm, δ4.5mm | Q345B Steel, Galvanised |

| Power Supply | Slide Contact Line System (Busbar) | |

| Floor Selection | Multi-functional Control System (Floor selector, Automatic Landing, Error Detection and Display, etc.) | |

| TUV proved according to European Regulation EN 12159:2012, EN 60204-1:2006/A1:2009. | ||

![]()